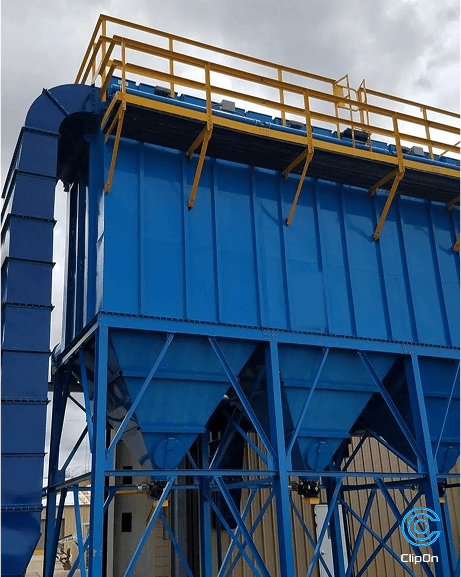

A bag filter traps dust and fine particles from the air as it passes through fabric media. It’s one of the simplest and most effective ways to keep exhaust streams clean before they’re released into the atmosphere.

Every industry faces its own kind of dust. What a cement unit sees isn’t what a food processing plant deals with. The trick is in picking the right filtration setup—not just any setup. ClipOn has spent years building filters that actually match real-world conditions instead of forcing the same mold on everyone.

Here’s what’s commonly used:

Each of these has its own role to play. And the real difference lies in the material used. Pick the right one and you’ll have a system that just keeps working, quietly in the background, year after year.

Some plants don’t have the luxury of a steady compressed air line. Others simply want a setup that runs without too much fuss. That’s exactly the kind of place where a reverse air baghouse makes sense.

Here’s how it plays out. Inside a rectangular housing, the filter bags hang down from a sturdy frame. Dust-laden air flows upward through the bags. Tiny particles get trapped inside the fabric, leaving cleaner air behind. Then the airflow reverses, gently collapsing the bags. The dust falls into the hopper below, neat and contained.

It’s not a noisy, high-pressure blast. It’s steady. Controlled. Predictable. And that’s why operators trust it.

A few more things that make it a solid pick:

This isn’t about fancy technology. It’s about something that works, day after day, in real heat, real dust, real conditions.

View our products now

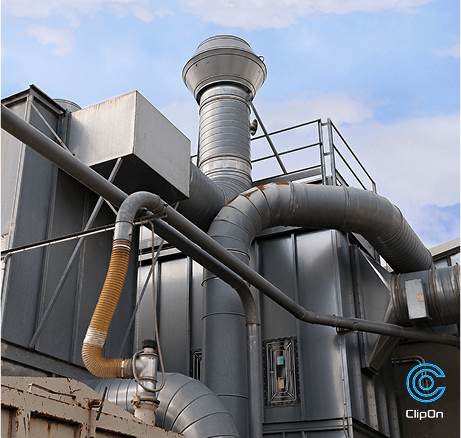

If you’ve ever had to wedge a filtration unit into a cramped plant layout, you already know space is a problem. That’s why cartridge collectors exist. They deliver the same job as a bigger unit but in a more compact frame.

They don’t just save space. They make maintenance easier too. Filters can be changed from the outside—no climbing into tight compartments or halting half the line just to clean the system.

Why people end up liking them:

Cartridge systems are especially popular in sectors like plastics and chemicals, where space and precision both matter.

The word “pollution control” sounds like a regulatory checkbox. But in practice, the right bag filter for air pollution changes how smoothly an entire plant operates.

You’ll find these systems across a wide range of industries, each using them a little differently:

Well-designed bag filters can collect over 99% of particulates. That level of efficiency is why they’re so widely used. It’s not just about compliance; it’s about keeping the air inside and outside cleaner—and the system itself running smoothly without constant stops.

When a company invests in filtration, it isn’t just buying equipment—it’s choosing how it wants to operate. At ClipOn, we have worked with industries that run 24/7, in places where shutting down just to clean filters isn’t an option. That real-world pressure is what shapes the way our solutions are built.

In short, it’s equipment you don’t have to keep worrying about.

Emissions have a way of catching up with industries—through regulations, through rising maintenance costs, and sometimes through the communities that live nearby. A bag filter for air pollution isn’t just a compliance box to tick; it’s a quiet shield working behind the scenes, protecting your people, your machines, and your reputation.

ClipOn doesn’t just sell filters. It builds practical, dependable systems that plant operators can actually live with. If you’ve been putting this decision off, this might be the right time to take the step.

View our products now

Because the systems are built for actual conditions, not ideal ones. They’re made to keep running without demanding too much from the operator. That alone makes a big difference on the shop floor.

Yes. All ClipOn filtration systems are designed to meet or exceed international environmental standards like ISO 14000, so compliance won’t be something you’re constantly chasing.

That depends on the dust load and how the system is maintained. But because these bags are built tough, they generally outlast many cheaper alternatives, which means fewer replacements and less downtime.

Absolutely. Many industries use a mix. Cartridges are used where the space is tight and baghouses handle the larger volumes. This combination gives flexibility and strong performance across different sections of a plant.